- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Biomass pellet machine

Author: Admin View: Post Time: 2015 / 08 / 25

Introduce of Biomass pellet machine

Our Lantian series high quality Biomass pellet machine absorbs the quintessence of various wood pellet mill both at home and abroad, the heart part adopts "double-layer ring die "as the unique structure. Biomass pellet mill machine function of agriculture and forestry processing wastes such as sawdust, straw, rice husk, bark biomass as raw material, through pretreatment and process, the curing forming for high density of pellet fuel The rollers are made by abrasion -proof alloy steel, our Biomass granulating machine with characteristics of unique design, rational structure, owe power consumption, high long lifetime. Our Lantian series high quality Vertical wood biomass pellet mill is applied to the material with low adhesiveness and low shaping (raw material),such as the rice husk, sunflower seed husk, peanut shell and other fruit shell branch, trunk, bark and other wood waste ;a variety of crop straws, rubber, cement, ash and other chemical materials. It can meeting the international demand of renewable compression biomass energy market. Biomass pellet mill machine as the main fuel of industrial boilers, coal-fired, solves the environmental pollution, What’s more, the pellet machines are our national patent products.

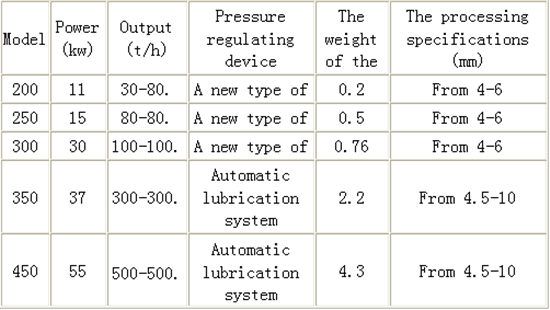

Technical Parameters of Biomass pellet machine

Features of Biomass pellet machine

1. Biomass granulating machine adopt high pressure filtration and lubricating systems.

2. Rollers are smoothly when working, its big body and unique design increase pressing place, increasing production efficiency.

3. Make the agro-forestry wastes into solid fuels or wood pellets.

4. After pelletizing, the length of the pellet can be cut according to different user's request.

5. Full Stainless steel strengthening feed conditioner, adopts the frequency-conversion speed regulating control to guarantee quality wood pellet.

6. The international advanced compensation type flexible coupling is of novel and compact structure, safety, low noise and less trouble.

Raw Materials for Biomass Pellet Machine

The raw material for Biomass fuel pellet machine can be the food grain like corn, wheat and the crushed waste from agriculture for example, corn straw, groundnut shell, grass, wheat bran, sawdust, and animal manure and so on

The molds of Biomass pellet machine

The final products of Biomass pellet machine

Biomass wood pellet machine main structures

Vertical wood biomass pellet mill is mainly composed of power system, granulating chamber, engine base, lubrication system, dedusting system and electric control system.

Our service

1. We treat customers as gods, and provide considerate services from shipment to maintenance, including professional free training, guidance, installation and debugging.

2. After sale, we provide one year's warranty. we will help to solve any mechanical problems in time. Also engineers are available to service overseas

The packaging and shipping of Biomass wood pellet machine

The customers visit our factory

Our certificates

Company information

Our main products are briquette machine, straw briquetting machine, Biomass pellet mill machine ,Vertical wood biomass pellet mill and biomass burning machine. Our factory produces the product range, product structure and unique design, high quality, reasonable price, our products are widely used in agricultural machinery industry and other industries. We stood in the perspective of the customer, put yourself in the customer's consideration, and combining with their own professional knowledge, a more reasonable process for the design of the customer, to produce more quality products. At the same time, we have rich practical experience and high quality design, manufacture, installation team, can according to customer needs, combined with the actual situation of the customer, manufacturing products best suited to customer needs.