- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Sawdust wood dryer

Author: Admin View: Post Time: 2015 / 08 / 22

Brief introduction of Sawdust wood dryer

The new type Wood chips dryer device enables real-time water vapor emitted from the top, and the end of the steam heat recovery and utilization, is a new type high efficient energy - saving drying equipment The Wood chips dryer than market surface common drum type drying device different, it use heat pipe indirect to materials heating, materials and heat source to full contact, steam to real - time from the top of device , heat source use hot - blast stove heating not consumption, with dry effect good, and structure reasonable, and output big, and energy consumption low, and install convenient, and operation simple, and to range wide such as advantage of, is feed such as powder materials the most ideal private device. The Wood shaving dryer machine can be adapted to the wood, straw and other raw materials, drying sawdust, rice husk, peanut shell, wheat, soybeans, sand, sawdust and other powder granule logistics, environmentally friendly, energy saving, is instead of the traditional drying equipment environmental protection energy-saving products

Performance characteristics of Sawdust wood dryer

1. The drying effect is good, fast, uniform heating, in the work in good liquidity, low drying cost

2. The moisture content 30% the left and right sides of a material can be to standard moisture 15%;

3. Large intensity of drying, due to the heat pipe and materials can be fully contact with, greatly increases the heat source materials and the area of effective contact.

4. High drying efficiency, energy saving and efficiency.

5. Flow speed of the material is controlled by frequency converter.

6. Low temperature of outlet air; long working time of dedusting equipment, which enables continuous production with next procedure.

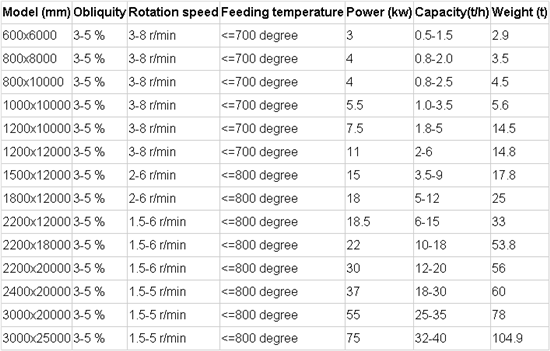

Technical parameter of Sawdust wood dryer

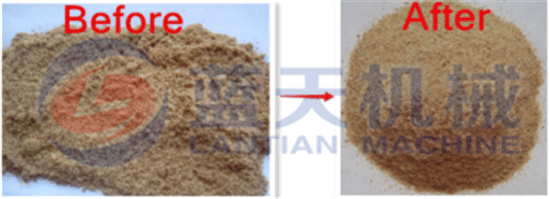

Compared before and after drying

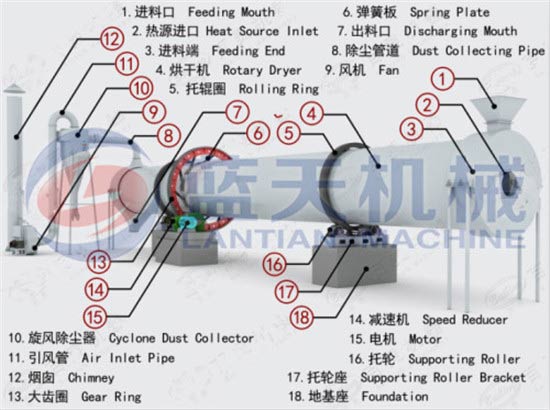

The details of Sawdust wood dryer

Working principle of Sawdust wood dryer

Customers visiting our factory

Packaging and shipping of Wood shaving dryer machine

The case

Our certifications

Our Services

1. Suggest to client suitable models of as customer need.

2. Introduce machine's structure and features in detail, explain the price component;

3. Send photos of machine in manufacturing and finished photos to client, for your better learn about the machine's condition.

4. Delivery Wood chips dryer in time, taking photos during loading, so you can "remote monitoring" your goods.

Company information

Our company to talent as a fundamental to innovation as the guide, unswervingly doing mining machinery main business bigger and stronger for a long time; On this basis, increase the intensity of market development and capital operation, actively seek new development space, careful pragmatic to explore new areas of strategy towards the goal of collectivization, internationalization development, to achieve the greater success of the Lantian machine foundation, to create conditions.