- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Belt dryer machine

Author: Admin View: Post Time: 2015 / 08 / 22

Description of Belt dryer machine

Lantian machinery production of Belt dryer machine is the use of steel network as a transport carrier material for continuous drying equipment. Is due to the conveyor belt mesh, so on baking rules or irregular lumps (such as: coal, carbon blocks of various mineral powder pellets, food, etc.) is the most appropriate. Conveyor mesh belt dryer and other equipment, can also be used alone. Coal briquettes mesh belt dryer can be widely used in metallurgy, building materials, ceramics, chemical fertilizers, chemical and other industries, and Belt dryer machine is for drying food and vegetable processing and an ideal equipment. Conveyor belt dryer is the material through the fabric of institutions such as Pelleting machine, distribution on the conveyor belt, conveyor mesh belt use 12 to 60 purpose steel mesh belt, conveyor belt by one or several heating unit consisting of a channel, by moving back and forth inside the transmission device drag in the dryer, each heating units are equipped with air heating and circulation system, each channel has one or more rows of wet system, the conveyor belt through the hot air in the materials passing through, the water vapor from the education in the platoon is wet hole, so as to achieve the purpose of uniform drying.

Features of Belt dryer machine

1. Big capacity, fast drying speed, high evaporation strength;

2. The standardization production, according to increase the number of production, easy installation and maintenance;

3. Convenient adjustment, drying parameters, such as can adjust the volume of hot air, heating temperature, residence time, etc., large elasticity of operation, adaptation of wide;

4. Dry material uniformity, good consistency;

5. The hot air recycling, high energy saving.

6. Conveyor belt dryer is fully enclosed structure. There no outer air pipes except the dehumidifying air pipe, thus the materials won’t be polluted and the heat efficiency and working condition are improved.

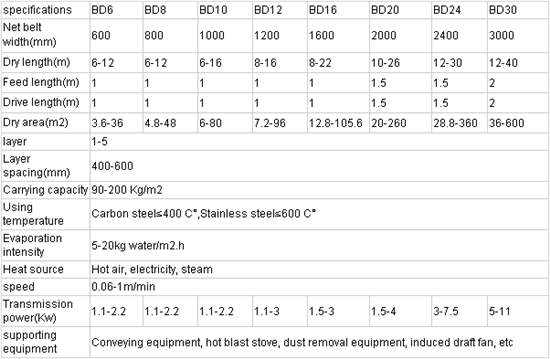

Technical parameter of Belt dryer machine

Application scope

Coal briquettes mesh belt dryer is a common continuous-working drying equipment. It can be widely used in chemical, pharmaceutical, foodstuff, building materials, and electron industries. It is especially suitable for drying the flaking shape, strip shape, and granule materials with good ventilating. To filter cake and cream materials, they can be shaped by granulator or extruder, and then be dried by belt dryer.

The details of Belt dryer machine

Working principle of the Belt dryer machine

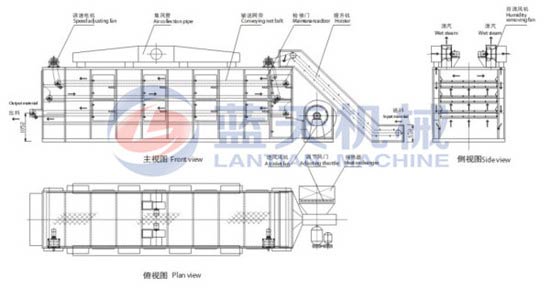

Conveyor belt dryer is the nose, drying section, the tail, mesh belt, transmission device, into the duct, air outlet, fan air (hot are another place), etc.

Material is the nose into the slowly through the drying, mesh belt speed according to the kinds of material and water content. To get the best drying effect and appropriate production, material, mesh belt linear velocity, distribution of the water content of the air and the wind temperature must be appropriate and reasonable, organic union.

Our foreign customers

Packaging & Shipping

Certifications

Our service

1. Before Sale: help you to set a purchase plan according to your requirement

2. During Sale: accompany you to check the performance of the machine

3. After Sale: Sent artisan to your place and help you with the installation

About us

Gongyi Lantian Machinery is located in Zhengzhou City, which is the biggest manufacturing base of charcoal making machinery. We will with the best product quality, the most enthusiastic service attitude, we will do our best to provide the most satisfactory services for the majority of the dryer users. Our factory code in accordance with the ISO9000 international quality system, set up the whole process of quality inspection system, strict quality control, to ensure that provide users with quality and reliable dryer equipment.