- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Coal slurry briquette machine

Author: Admin View: Post Time: 2015 / 08 / 17

Brief introduction of Coal slurry briquette machine

The Coal slurry briquette machine is widely used in mining production line, coal industry and chemical industry. Many kinds of raw materials are suitable for the Coal sludge briquette making machine. Such as coal powder / coal fine/ coal dust/ coal slurry, charcoal powder / charcoal fine/charcoal dust, all kinds of metal powder and other raw materials. Coal slurry pressure ball machine has the properties of high efficiency, energy saving and environment protection. Through changing the mold of the roller, it can press different shapes ball. The shape of end product can be round, square, pillow and so on. Now after dried through a drum dryer, coal slurry can be compress into solid briquettes. The briquettes heating value is improved as moisture is reduced.

Solid briquettes are strong for transportation and storage. Coal slurry ball press machine is applied in power plant, large industrial boilers and home warming.

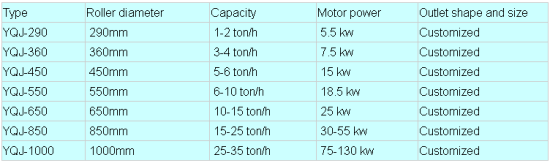

Technical references of Coal slurry briquette machine

Specifications

Coal slurry briquette machine

1. High briquette ratio.

2. Excellent working performance

3. High strength

4.CE and ISO

Main features of the Coal slurry briquette machine

1. High strength, good toughness, wear-resisting performance is good.

2. Coal sludge briquette making machine is Energy saving, friendly-environment

3. Easy to transport and improve the utilization of waste.

4. The Coal slurry pressure ball machine can produce products with different shapes and specifications by changing the roller;

5. Multi-use, it can make different material briquettes.

6. Easy operation and no flying dust

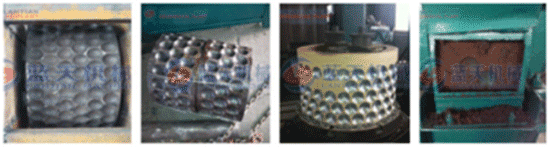

The molds of Coal slurry briquette machine

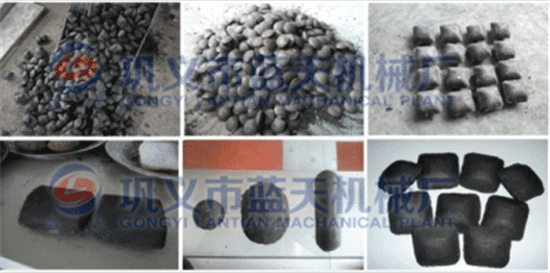

The final products of Coal slurry briquette machine

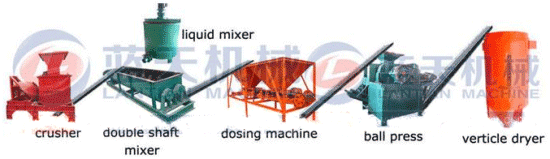

The whole production line related to Coal slurry briquette machine

With the help of the belt conveyor, the material got into the feed inlet of the Coal slurry ball press machine steadily. The raw material was put into the space between the two rollers well- proportioned, pressure between the two contact speed reverse moving direction getting higher, and reach the highest level in the center, line of the two rollers. After the raw material pass the center line, the molding pressure getting lower and make the raw material turn into ball and get off the machine.

Our Services

1.If any interest in our Coal slurry ball press machine ,please feel free to contract me and let me know your requirement on capacity and material size.

2.We are professional machine manufacturer, we will help to choose the most suitable machine for you.

3. Quality Commitment: Quality Warranty, Grantee Period: 1 year. Supply wearing parts with favorable price and long term after-sales service.

4.If you need, we will dispatch professional engineer for installation, trail and worker training.

Our customers from different countries

Packaging & Shipping of Coal slurry briquette machine

Certifications

Company Information

our company makes a series of a complete set of automatic production line for pulverized Coal slurry briquette machine, Coal slurry pressure ball machine, Coal sludge briquette making machine,Coal slurry ball press machine, it is widely used in power plants, metallurgical, chemical, energy, transportation, heating and other industries, after pressing ball mechanism for forming material, has the characteristics of energy conservation and environmental protection, easy to transport, and improve the utilization of waste, has the good economic efficiency and social benefits.