- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Fly ash dryer

Author: Admin View: Post Time: 2015 / 08 / 21

Brief introduction of Fly ash dryer

Fly ash dryer for initial moisture content is higher than other material, proportion of fly ash is smaller than other materials, the characteristics of the change of liquidity in the drying process is designed, with compact structure, covers an area of less, reliable operation, low energy consumption, high thermal efficiency, material drying effect is good, easy to realize automation control, less operators. Lantian machinery production of Fly ash drying equipment can be used in cement, mining, building materials, chemical industry, food, such as compound fertilizer production of material drying, mainly by the cylinder device, front and rear wheel device, front-rear device, transmission device and the gear cover parts. Fly ash rotary drum dryer has been widely used to dry slag, clay, coal, iron powder, mineral powder and other mixed material in various industries, to dry dry-mixed mortar, yellow sand etc in construction industry, and to dry raw materials in chemical industry and casting industry.

Performance characteristics of Fly ash dryer

1, The low temperature, dust removal equipment with long time.

2, The new type of composite feed device, can according to user requirements of regulation to easily indicator;

3, A high degree of automation, convenient operation, stable running;

4, The equipment investment is needed for imported products 1/6, small investment, income fast;

5, Fly ash drying equipment for new energy-saving products, energy saving about 20% than the same product category;

6, Fuel can be coal, oil, steam, etc.

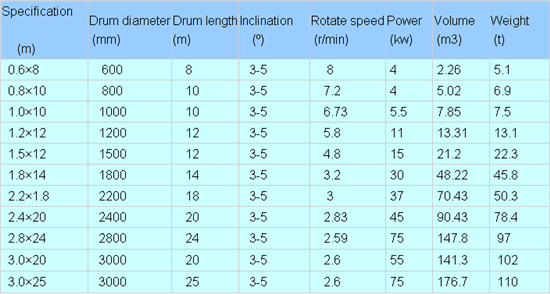

Technical parameter of Fly ash dryer

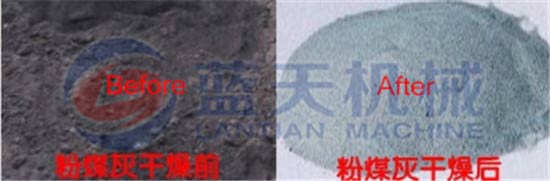

Compared before and after drying

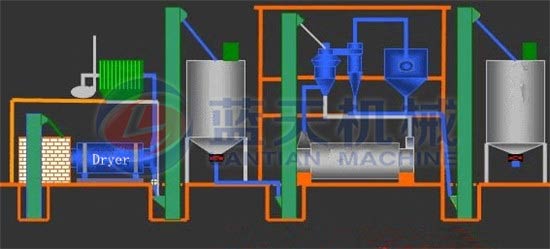

Working principle of Fly ash dryer

Powder or granular fly ash by belt type feeder to the feeder, again by feeder to fly ash conveying in dry inside the cylinder, the fly ash in a drying drum under uniform of copy board flipping, evenly dispersed in contact with the hot air fully and achieve drying of heat and mass transfer. After drying of the fly ash in the roller end by discharger discharge finished product, by avoiding the output belt discharging machine, complete the drying process.

The case

Customers visiting our factory

Packaging and shipping

Our certifications

Our Services

1. Installation and adjustment of the machine: Technicist will be provided by supplier for buyer to assist the work such as welding connection of shell body, equipment installation, adjustment, training, etc.

2. Technical support of rotary dryer is provided from the beginning to the end.

Company information

Lantian machinery was founded in 1980s, and now it has been becoming a high-tech mining company. The brand products, Fly ash rotary drum dryer, sand making machine, high-efficient fine crusher, high-pressure medium-speed mill, vertical mill, Fly ash drying equipment etc, and all the products have gained ISO9001: 2008 quality management system certificate At present has formed scale, standardization, service integrated marketing system, which is in the leading position in the industry.