- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Vinasse rotary dryer

Author: Admin View: Post Time: 2015 / 08 / 22

Brief introduction of Vinasse rotary dryer

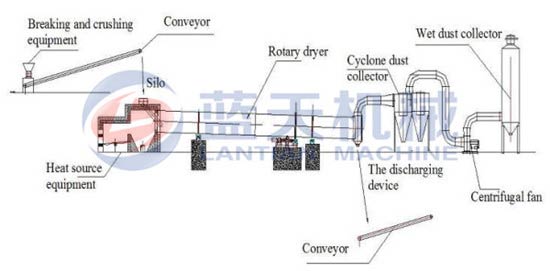

Vinasse rotary dryer is dedicated to high humidity material drying (w > 50%), such as: vinasse, bean dregs, fruit slag, furfural extract, sawdust, fish meal, animal feces. The Corn husk rotary dryer according to equipment structure, drive system, sealing system, the heat exchange system, drying system for 50 numbers of technology improvement, research and development success. Lantian machinery production of Feed dryer machine can rapid moisture content in about 85% of the wet brewer's grains after dehydration, drying to 10% moisture content in dried, at present this set of equipment has been in the beer more than domestic enterprises, feed processing enterprises, and create considerable economic benefits. Corn husk rotary dryer mainly consists of heating source, feeding machine, feeding machine, rotary drum, discharging machine, induced draft fan, the discharger and distribution; Wet brewer's grains into the dryer after dehydration, uniformly distributed in the drum of copying turning plate, evenly dispersed in the Feed dryer machine and a good contact with the hot air, to speed up the drying heat transfer, mass transfer. In the process of drying, brewer's grains with gradient copy board and under the action of heat medium, to another period of star discharge valve to discharge the dryer drying product.

Performance characteristics of Vinasse rotary dryer

1. The drying high mechanization degree, large production capacity, can work continuously.

2. The structure, simple, good material through the barrel resistance smooth operation, easy to operate.

3. Less failure, low maintenance cost, low power consumption.

4. The uniformity of product drying is good.

5. Great operating flexibility, the output of the products allows a larger fluctuation range, not influencing the quality of the products.

6. Adopt the special break up device, ensure that the effect of the dryer is well.

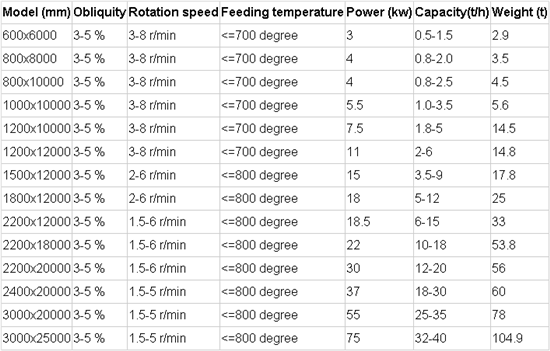

Technical parameter of Vinasse rotary dryer

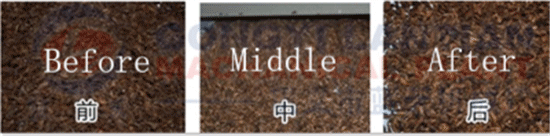

Compared before and after drying

Working principle of Vinasse rotary dryer

Dehydrated beer lees will be uniformly dispersed in the Feed rotary dryer after entering the dryer so that they can get full contact with the hot air with the lifting plate flipping in the roller, which speed up the drying heat and mass transfer. During the drying process, the beer lees will be dried into end products and discharged through the star discharge valve at the other end of the dryer in effect of the sloping lifting plate and heat medium.

Customers visiting our factory

Packaging and shipping

Our certifications

Our Services

1. Professional engineer design the production line for you

2. Send technicians to the jobsite for guiding the installation and adjustment

3. Common problem can be solved through web in 24 hours, complex problem can be reacted immediately in 24 hours and solved as soon as possible

4. To establish long-term friendship, we will regularly contact with our customers.

Company information

Our company depend on experience advantages and technological innovation ideas we make research on new type and high efficiency rotary dryers, Vinasse rotary dryer, Feed dryer machine,Corn husk rotary dryer,vertical dryers, indirect dryers for high humidity and viscosity materials such as raw coal, coal slime, lignite, sludge, waste, fly ash, gypsum, manure, lees, mine slime, etc. Companies adhere to the "to the quality strives for the survival, to the credibility of development" policy, develops the market, service users, achieved good social benefits and economic benefits, the product has for years been sold well all over the country and exported abroad, well received by users.My company is willing with the latest technology, reliable quality, preferential prices, all to the user as the center, promote customer satisfaction engineering, with new and old customers sincere cooperation, a total of brilliant innovation century.