- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Coal gangue dryer

Author: Admin View: Post Time: 2015 / 08 / 21

Brief introduction of Coal gangue dryer

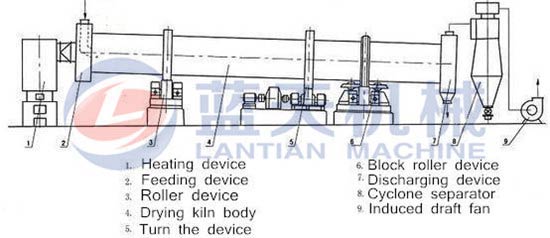

Coal gangue dryer is a type of industrial dryer employed to reduce or minimize the liquid moisture content of the material it is handling by bringing it into direct contact with a heated gas. The Gangue drying machine is made up of a large, rotating cylindrical tube, usually supported by concrete columns or steel beams. The Coal gangue tumble dryer consists of rotary body, throwing flitch, transmission device, supporting device ,sealing ring, heat source, beater device, belt loading machine, feeding machine, rotary roller, belt discharger, draft fan, discharger, and switch board. Before drying, the coal gangue needs to crush first, the crushed material enters the Coal gangue tumble dryer, Material to be dried enters coal gangue dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer. When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls.

Performance characteristics of Coal gangue dryer

1. The Coal gangue tumble dryer has a large capacity, less fuel consumption

2. The Gangue drying machine has the characteristics of high temperature resistant, can makes materials be dried at high speed, high temperature hot air.

3. This Gangue drying machine adopts the self-aligning type tug structure, greatly reduces the wear and power consumption.

4. Specially designed gear wheel structure, greatly reduced due to the equipment working tilt horizontal thrust.

5. Resistance to overload ability, cylinder smooth operation, high reliability.

6. The granularity and the moisture and be controlled by the customer’s demand.

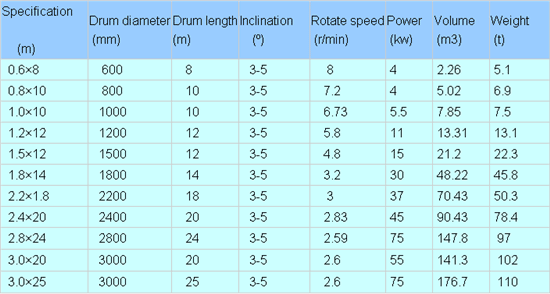

Technical parameter of Coal gangue dryer

Compared before and after drying

Working principle of Coal gangue dryer

The raw material plate is arranged conveniently to allow adjustable angle positions. The material to be dried is inserted to the rotary cylinder through the raw material plate. Hot air flows within the cylinder causing the separation of water from the material by converting it into vapor which is discharged into the atmosphere. At this point, the material becomes dry.

The case

Customers visiting our factory

Packaging and shipping

Our certifications

Our Services

1. Guide our customers to deploy the most useful equipment item according to the requirement of theirs.

2. Provide technical detain including equipment bill layout base specification and installation picture to consult

3. Design and manufacture product according to the customers' special requirement

4. Dispatch the technical person to reach the locale to layout field design the best installation flow and scheme to consult for free

Company information

Gongyi Lantian Machinery was started in 1980s, which is a professional enterprise integrating in R&D, production and sale in mineral equipments. Our company has a modern heavy industrial plant, the processing equipment is complete .Mainly introduced the dryer equipment has: small dryers dryer, Coal gangue dryer,Gangue drying machine,Coal gangue tumble dryer sludge dryers, lignite dryer, rotary dryer, double drum dryer, the three-cylinder dryer, grain dryers, quartz sand dryer, drying equipment, such as welcome customers come to visit our factory to choose!