- Coal slurry briquette machine

- BBQ charcoal making machine

- Charcoal powder briquette machine

- Coke powder briquette machine

- Lignite coal ball press machine

- Olive charcoal briquette machine

- Coconut charcoal briquette machine

- Coal ball press machine

- Carbon black press machine

- Mineral powder briquette making machine

- Iron ore powder briquette machine

- Desulfurization gypsum ball press machine

- Lime ball press machine

- Carbon ball press machine

- High pressure dry powder ball press machine

- Hydraulic press machine

- Coal gangue ball press machine

- Hydraulic steel reinforcement machine

- Hydraulic powder press machine

- Hydraulic solid alcohol fuel machine

- Hydraulic coking coal machine

- Hydraulic coal powder press machine

- Hydraulic sawdust making machine

- Hydraulic bamboo charcoal briquette machine

- Hydraulic coconut shell charcoal press machine

- Hydraulic BBQ charcoal machine

- Hydraulic hookah charcoal briquette machine

- Hydraulic charcoal powder briquette machine

- Wood carbonization furnace

- Biomass carbonization furnace

- Wood charcoal carbonization furnace

- Sawdust dryer

- Wood crusher machine

- Sawdust crusher machine

- Straw crusher machine

- Wood charcoal briquette machine

- Sawdust extruder machine

- Rice husk briquette machine

- Straw briquette machine

- Biomass extruder machine

- Coconut shell briquette machine

- Cotton stalks briquette machine

- Sawdust briquette machine

- Alfalfa coal briquette machine

- Biomass straw coal briquette machine

- Rice husk briquetting machine

- Peanut shell briquette machine

- Straw coal machine

- Bagasse briquette machine

- Automatic packaging machine

- Edible fungi bag briquette machine

- Furfural slag briquetting machine

- Alfalfa coal briquette machine

- Straw hammer crusher

- Wood crushing machine

- Sawdust crusher

- Straw forage ensilage machine

- Coffee husk briquette machine

- Single agitator

- Straw pellet press machine

- Rice husk pellet mill machine

- Biomass pellet machine

- Wood grinder machine

- Straw cutter machine

- Wood log chipper machine

- Wood template crusher

- Wood chips rotary dryer

- Wood pellet machine

- Particle combustion machine

- Production line

- Belt conveyor machine

- Screw conveyor

- Bucket elevator

- Drum screen sieve

- Vibrating screen machine

- Cyclone dust collector

- Counter flow cooler

- Particle weighting packing machine

- Airflow dryer

- Iron powder dryer

- Rotary dryer

- Vinasse rotary dryer

- Pomace rotary dryer

- Sawdust wood dryer

- Indirect dryer

- Petroleum coke dryer machine

- Desulfurization gypsum dryer

- Chicken manure dryer machine

- Clay dryer

- Bagasse dryer

- Slag dryer

- Coal gangue dryer

- Fly ash dryer

- Lignite dryer machine

- Coal powder dryer

- Sand dryer

- Coal slime dryer machine

- Sludge dryer

- Ore balls vertical dryer

- Straw powder airflow dryer

- Airflow wood dryer

- Charcoal briquette dryer

- Hookah charcoal dryer

- Coal rods drying machine

- Box-type dryer

- Type coal dryer

- Wood chips drum dryer

- Belt dryer machine

- Biomass dryer machine

- Waste iron scrap crusher

- Metal can crusher

- Waste paint pot metal crusher

- Waste rubber crusher machine

- Waste refrigerator crusher machine

- Scrap car crusher

- Scrap steel crusher machine

- Scrap aluminum crusher

- Color steel tile crusher

- Metal crusher

- Waste tire crusher

- Waste computer board crusher

- Waste metals bicycle crusher

- Glass bottle crusher machine

- Tea tin can crusher machine

- Electronic waste crusher

- Waste battery crusher

- Radiator scrap crusher

- Waste gate crusher

- Thin plastic scrap crusher

- Scrap tanker crusher machine

- Scrap oil filter crusher machine

- Walnut kernel oil machine

- Jatropha seeds oil press machine

- Tung cold oil press

- Screw pepper seed oil press

- Avocado seed oil press

- Hazelnut oil press

- Rice bran oil press machine

- Flaxseed screw oil press

- Almond oil press machine

- Screw oil press mill

- Cotton seed oil expeller

- Castor bean oil press machine

- Walnut kernel oil press machine

- Sunflower oil press machine

- Grains oil press

- Sesame screw oil press machine

- Soybean oil press machine

- Rapeseed oil press machine

- Tea seed oil press machine

- Peanut oil press machine

- Corn oil press machine

- Papaya seed oil machine

- Feeding machine

- Steam frying pan

- Sesame oil machine

- Frying pan machine

- Oil tea seed removing machine

- Peanut shelling machine

- Walnut shelling peeling machine

- Centrifugal filter oil filter

- Carbonization stove

- Dust collecting machine

- Mining circular vibrating screen

- Drum screen machine

- Liquid mixer

- Vertical chain bucket elevator

- Horizontal screw conveyor system

- Automatic feeder

- Spiral mixer

- Dual-axis mixer

- Wheel roller mixer

- Crushing and mixing machine

- Flexible screw conveyor

- Movable inclined belt conveyor

Indirect dryer

Author: Admin View: Post Time: 2015 / 08 / 22

Description of Indirect dryer

Indirect dryer is used for drying materials with humidity or granularity in the industries of mineral dressing, building material, metallurgy and chemical. Indirect drum rotary dryer can be used for drying many kinds of materials sawdust, wood powder, Fruit slag, slag. Bagasse, grain, feed etc. And it formed by rotary body, lifting blade, driving device, supporting device and sealing ring. The Indirect heating dryer has advantages of reasonable structure, high efficiency, low energy consumption and convenient for transportation, and convenient and reliable operation; Therefore, the consumption of the coal and the electricity is lower than the common ones. This Indirect drum rotary dryer mainly consists of revolution body, lifter, and gearing, supporting device and seal ring etc components. Indirect heat rotary dryer has features of reasonable structure, high output, strong adaptability, low energy consumption, easy operation, etc. Indirect heating dryer is mainly used for dryer dressing, building materials, metallurgy, and chemical etc industries for drying certain humidity or particle materials.

Features of Indirect dryer

1. Indirect heating dryer has Strong anti overload ability, large handling capacity, less fuel consumption, low dry cost.

2. According to different materials' properties change operation parameters, make the material in the dryer cylinder body can form a stable all broken fabric curtain, qualitative heat is more fully.

3. Barrel self insulation thermal efficiency can reach above 70%, increase thermal efficiency is 35%

4. The material moisture to ensure below 0.5%, dry mortar and slag powder production line is the preferred dryer;

5. Covers an area of about 50% lower than single drum dryer and civil investment to reduce 50%, power consumption reduced by 60%;

6. Can according to user requirements of regulation to easily indicator;

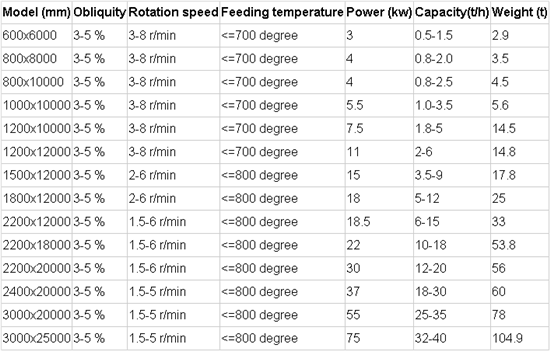

Technical parameter of Indirect dryer

Indirect dryer applicable scope

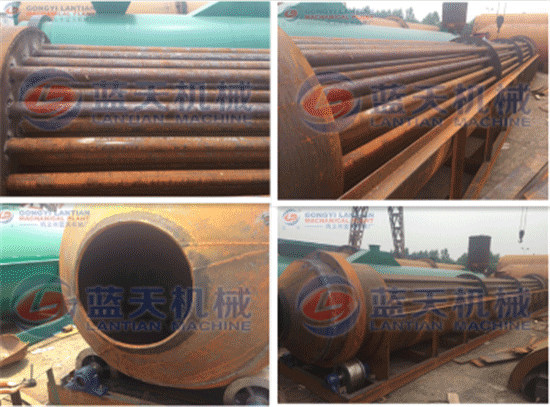

The details of Indirect dryer

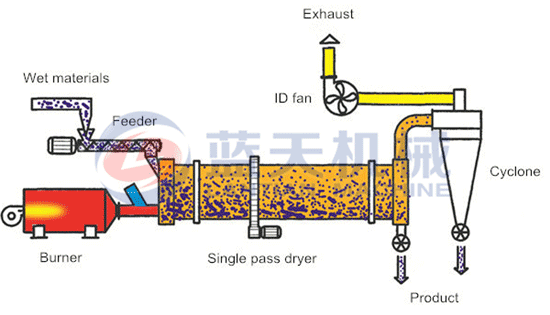

Working principle of the Indirect dryer

Indirect air heater--With coal, natural gas or firewood as energy resources, the direct heat is induced by draft fan into the pipe where there is heater strip. Then the heater strip is heated by the direct heat after then the indirect heat goes into to drying oven. By drying with indirect heat, the cassava slices can be dried evenly.

Our foreign customers

Packaging & Shipping

Certifications

Our service

(1) Device model choice.

(2) According to customer's special requirements, design and manufacture of products.

(3) Training technical personnel for clients.

(4) The company is free of charge to the user on-site engineering and technical personnel planning site for the user to design the best processes and program

About us

Lantian Machinery was founded in 1980s, aiming to serve the need in mining, metallurgy, construction, chemical industry etc. For over 30 years, the Lantian machinery always adhere to the "strives for realism the innovation, forge ahead" business philosophy, focus on the production quality and develop new products, seek development by science and technology, the flexible design thought and strict craft standard amalgamation into an organic whole, with modern advanced technology to guide product upgrading.